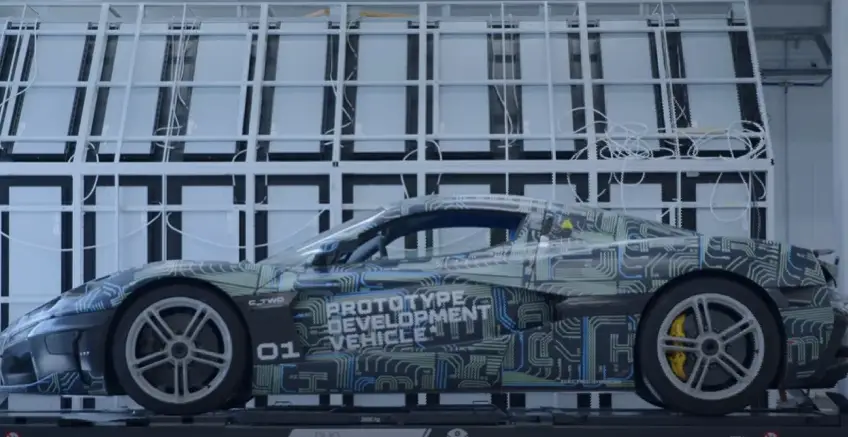

As Novac writes on the 17th of June, 2020, Mate Rimac and his company Rimac Automobili have unveiled the next stage in the development of the amazing C_Two car – a brand new production line.

At the recently opened Rimac production plant in Veliko Trgovišće, the line will accelerate the production of C_Two prototypes required for final validation and the testing necessary for homologation worldwide. Assembling each C_Two car will take approximately five weeks, halving the production time when compared to the principle of static production, which is a method used by some other supersport car manufacturers.

When operating at full capacity, the new process will enable the construction of four final production vehicles per month. However, at Mate Rimac’s company, the production process starts much earlier, before the assembly of finished components on the line. This is because a large number of components and systems are produced at the factory in Sveta Nedelja and in Veliko Trgovišće, after which it is delivered to the vehicle assembly line.

The new production line is divided into five main zones, and it begins with the attachment of all of the brackets and attachment points to the carbon construction of the vehicle. The two technicians at each subsequent station then proceed to assemble the car piece by piece. Subassemblies such as the dashboard, front radiator and other parts are manufactured and prepared off-line and are delivered completed and ready for installation on the vehicle assembly line.

So far, Mate Rimac and his company have produced four C_Two prototypes, and thirteen more are needed before the testing and homologation process is completed, followed by ten more pre-series cars, most of which will be produced this year. The complete homologation process (without any shortcuts) from the first concepts, through to complete prototypes to cars on the road is a three-year process. With the introduction of the new production line, Rimac Automobili will deliver the first cars to customers in 2021, unlike the original plan before the COVID-19 crisis which foresaw deliveries taking place this year. The final design and name of the car will be revealed this year.

“We’ve worked hard to bring the C_Two to the stage it’s at now and we want to enable our customers around the world to experience the performance of a fully electric 1914 horsepower car as soon as possible. We have chosen the path of ”full global homologation” without shortcuts, for which we have to perform a rigorous development and testing process, including many crash tests that require many different prototypes, each with its own purpose. While some of the cars will go straight from the production line to the crash testing plant, others will be used for different validation tests. Only a few prototypes, which aren’t going to be used for crash testing, will survive the testing cycle. Given that we’re now in the phase of raising the pace of production, this new line is absolutely necessary to speed up the process, which will allow us to start delivering the cars next year,” said Mate Rimac, the founder and CEO of Rimac Automobili.

The Rimac C_Two promises a top speed of 412 km/h, an acceleration time of 0-62mph (100km/h) in 1.9 seconds and an acceleration time of 0 – 161 km/h (100 mph) of 4.3 seconds. These outstanding performances have been set as the ambitious goals of Mate Rimac and his dedicated team with the first announcement of the C_Two car back in 2018, and thanks to the extensive development and testing of the car, the engineers are confident that those challenging goals will be met.

In parallel with the development of C_Two, Rimac is continuing to grow as a company, and Porsche has as such increased its ownership stake in the company to 15.5 percent, while the Hyundai Motor Group invested EUR 80 million, joining such a long list of already established customers and partners of Rimac such as Koenigsegg and Aston Martin.

Watch the video below:

For more on Mate Rimac and other Croatian entrepreneurs, follow Made in Croatia.